Planting seeds

In early February, sweet potato seeds are planted in greenhouses. It takes about a month and a half for the seeds to grow, meanwhile, the temperature and humidity of the greenhouses is carefully monitored.

Each year, during the production season, we engage and struggle alongside our producers in a three-legged race against an ever-changing nature while hoping for the best.

During this period, the master and other brewers stay at the brewery throughout the entire process pushing the facility to its limits 24 hours a day. This is most definitely a relentless struggle !

Kōji requires particular attention, the best result comes from understanding the kōji mold. The brewing of each brand is managed according to a meticulous schedule, even the bottling process is done with safety as its top priority. Together, our challenge continues to keep on delivering a better-tasting shōchū.

In early February, sweet potato seeds are planted in greenhouses. It takes about a month and a half for the seeds to grow, meanwhile, the temperature and humidity of the greenhouses is carefully monitored.

While the seeds are growing, ridges are made in the field. The sweet potato seedlings are then planted on these ridges.

Early April is when planting the seedlings out starts. Once they have grown to about 25 centimeters, the seedlings are cut off and replanted in the field. Over the next 150 days, the seedlings will bathe in sunlight and slowly grow into delicious sweet potatoes.

Early September is when the sweet potato harvest begins. The sweet potatoes’ vines are cut off and dug up from the ridges. The beard roots are removed, and the sweet potatoes are placed in a flexible container bag that will be delivered to the brewery the very next day.

To make kōji, the rice bran and other debris are washed away.

Water is put together with the rice in a drum allowing it to absorb the water. The absorption time varies depending on the size and type of grain.

After having been soaked, the rice is steamed, causing the starch to gelatinize, making it more susceptible to the enzymatic action of kōji. The steamed rice becomes hard on the outside and soft on the inside.

Seed kôji is then sprinkled over the steamed rice and cultivated for about 40 hours. Kôji produces glycolytic enzymes that convert starch into glucose and citric acid protecting the unrefined sake from bacteria.

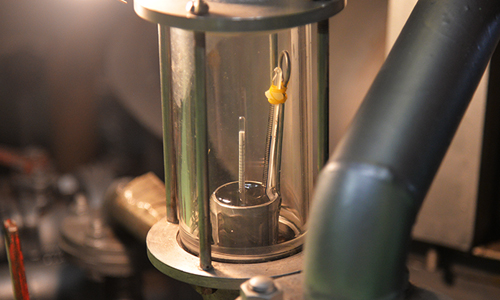

Kōji is then put together with yeast and water in a tank in order to multiply the yeast. The yeast is the source of unrefined sake, which is why it is called 酒母 shubo (sake mother) in Japanese. The process takes about 6 days during which the temperature needs to be monitored.

The sweet potatoes come in the day following their harvest. At this point, they are still covered in dirt and need to be washed clean with water.

The washed sweet potatoes are then sorted. Any diseased or damaged parts are removed and the sweet potatoes that are too large are split to ensure size homogeneity. Sorting is an essential process as it affects the flavour of the finished shōchū.

After being sorted, the sweet potatoes are placed in a steamer. The steaming time depends on the variety, size, and harvest time of the sweet potatoes.

The steamed sweet potatoes are cooled down to a suitable temperature before being crumbled and put together with water and yeast in a tank to brew. Once this is done, the preparation is transferred to fermentation tanks to undergo alcoholic fermentation.

The sweet potatoes will be left to ferment for about 9 days. Inside the tank, the saccharification enzyme of the kōji will cause the starch to turn into glucose that will be metabolized by the yeast to produce alcohol.

The aromatic component of shōchū is also produced in this process.

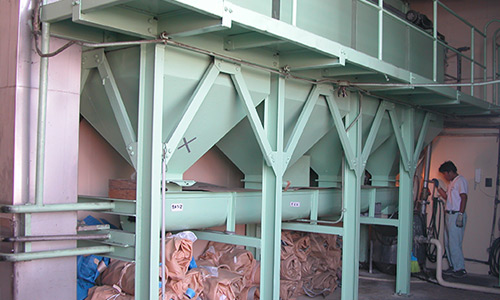

Once the fermentation process is done, the preparation is transferred to the distillation machine. The traditional atmospheric distillation produces a rich, sweet potato aroma while vacuum distillation produces a fruity, flowery aroma. The refined shōchū is 38% alcohol by volume.

After distillation, the excess oil and foreign bodies are filtered out, the refined shōchū is then left to mature in tanks. During the process, the gas and such escape resulting in a mellower shōchū.

The refined shōchū is then diluted with water to bring the alcohol down to 25% by volume. The taste right after dilution is rough so it needs to be matured for about a month in tanks.

A month after the dilution, the taste has settled down and the shōchū can be bottled.

Bottling is conducted with meticulous care to ensure that no foreign bodies get mixed in. Finally, the bottle is checked by the human eye.

Skilled inspectors can notice even a 0.5 mm discrepancy on the label.

The finished products are then shipped all over Japan.